|

|||||||

|

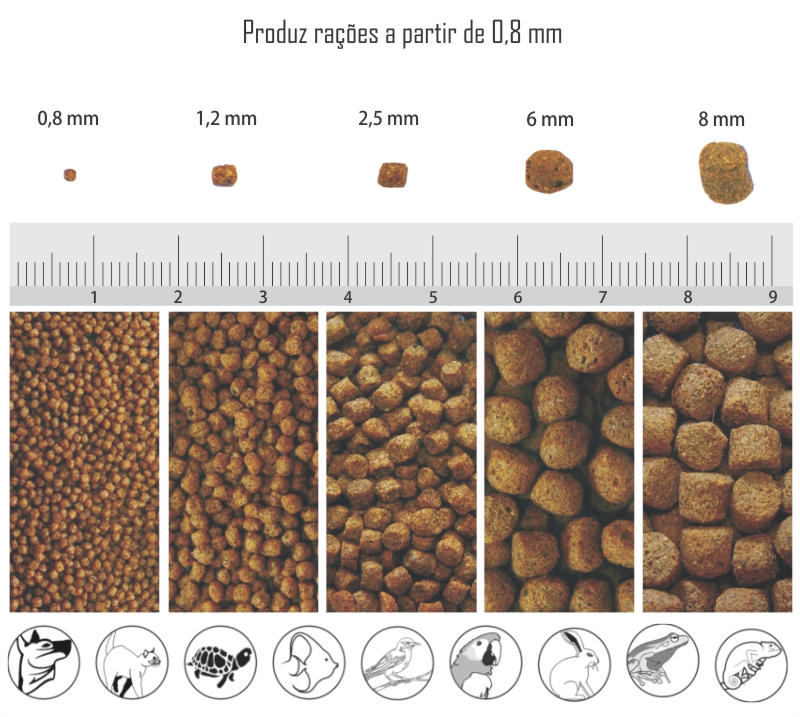

Capacity 40/60/150/300/500 Kg/h

Manufactured in stainless steel

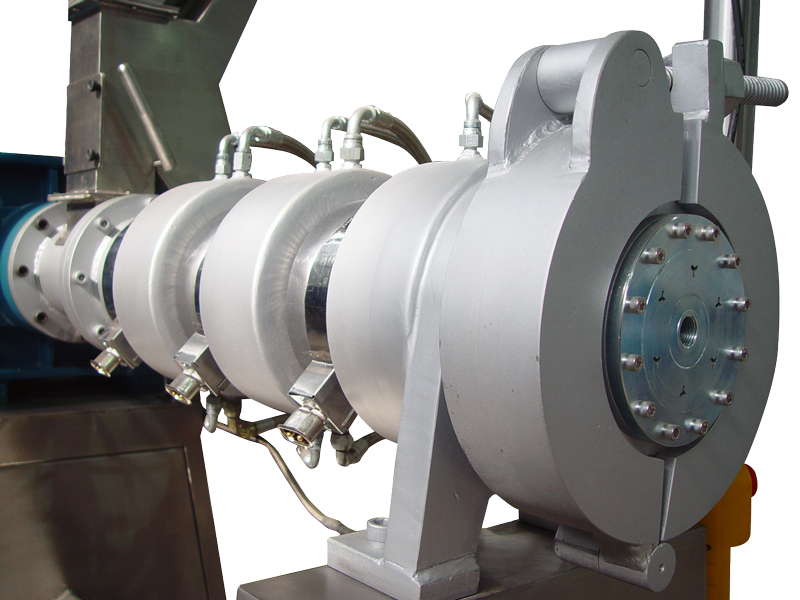

EXTRUDER: Structure, electrical board, cooling cameras, silo, lateral covers and exit tap totally built in stainless steel. Start up by triphasic electrical engine, with variable rotation, by frequency inversor. Cutting system with variable rotation, start up by triphasic electrical engine and frequency inversor. Electric board with a first-line components . Extrusion shirt modulated, monoblock system with helical screws. Extrusion screw, with composable modules, with several options of fitting.

Optional: Extrusion cannon with capillar for steam injection and transducer for pressure measure.

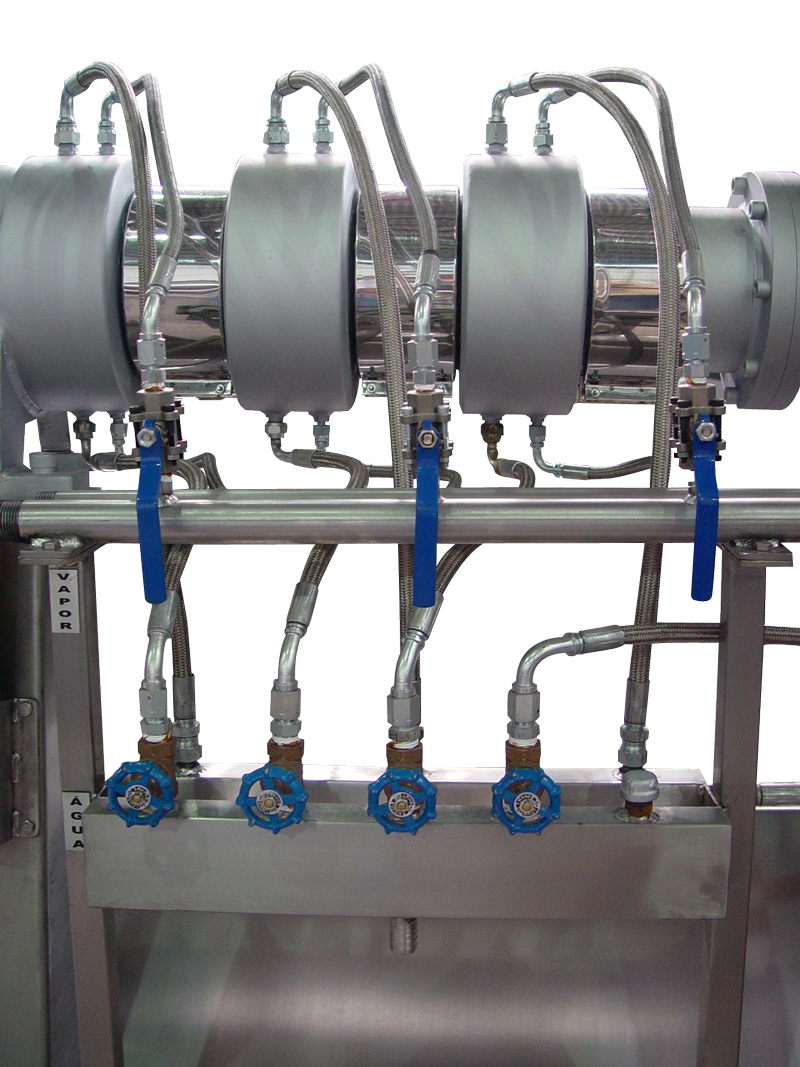

CONDITIONER: Manufactured in stainless steel, owning internal blades for homogenizing the product, start up by triphasic reducer engine, with variable rotation by frequency inversor. It owns “rotametro” for continual water feeding.

Optional: Entrance for steam injection, steam distributor with circled valves and manometer.

FEEDING CONDITIONER: Manufactured in stainless steel, with helical screws for feeding. Start up by triphasic electrical reducer engine with variable speed by frequency inversor.

SILO WITH SHAKER: Manufacture in stainless steel with internal propellers for homogenizing and mix the product in the mixture screw of conditioner. Start up by triphasic reducer engine.

DRYING DRUM: Continual rotary drum, built in stainless steel, owning internal room for recirculating the product, with external thermical isolation of pottery fibre 600 degrees. Structure and bearing tracks manufactured in stainless steel. Start up by reducer engine, with variable speed by frequency inversor.

DRYING SYSTEM: Through fire boiler built in stainless steel thermically isolated. Gas burner system, start up by digital thermocontroller, with high and low fire controller. Turbo fan coupled in the upper part of the boiler for impulsing hot air in the drying drum.

APPLICATION DRUM: Continual rotary drum, built in stainless steel, owning internal room for recirculating the product. Structure and bear tracks manufactured in stainless steel. Start up by speed reducer engine.

VITAMINE MIXER/PROBIOTIC: Built in stainless steel, owning: centrifugal pump for recirculating and homogenizing the product, peristaltic pump start up by reducer engine with variable speed controlled by frequency inversor. Spray system through spray tap manufactured in stainless steel.